Reflector Facing Technology is becoming an increasingly popular solution in the automotive market.

Their authority has its reasons.

RFT provides many opportunities for competitive advantage for commercial vehicle manufacturers and truck manufacturers.

And at the same time, it keeps costs low.

More light at a lower purchase cost, fewer diodes and less power consumption. Is this possible? These are the advantages of LED lights constructed using reflector technology - free halves FF (Free Fields or Free Forms) and RFT (Reflector Facing Technology).

The reflector of the headlights is made up of a number of irregularly placed mirrors, the shape of which can be precisely formed by computer in order to make the most of the light emitted by the LEDs and to direct its beam in the best possible way.

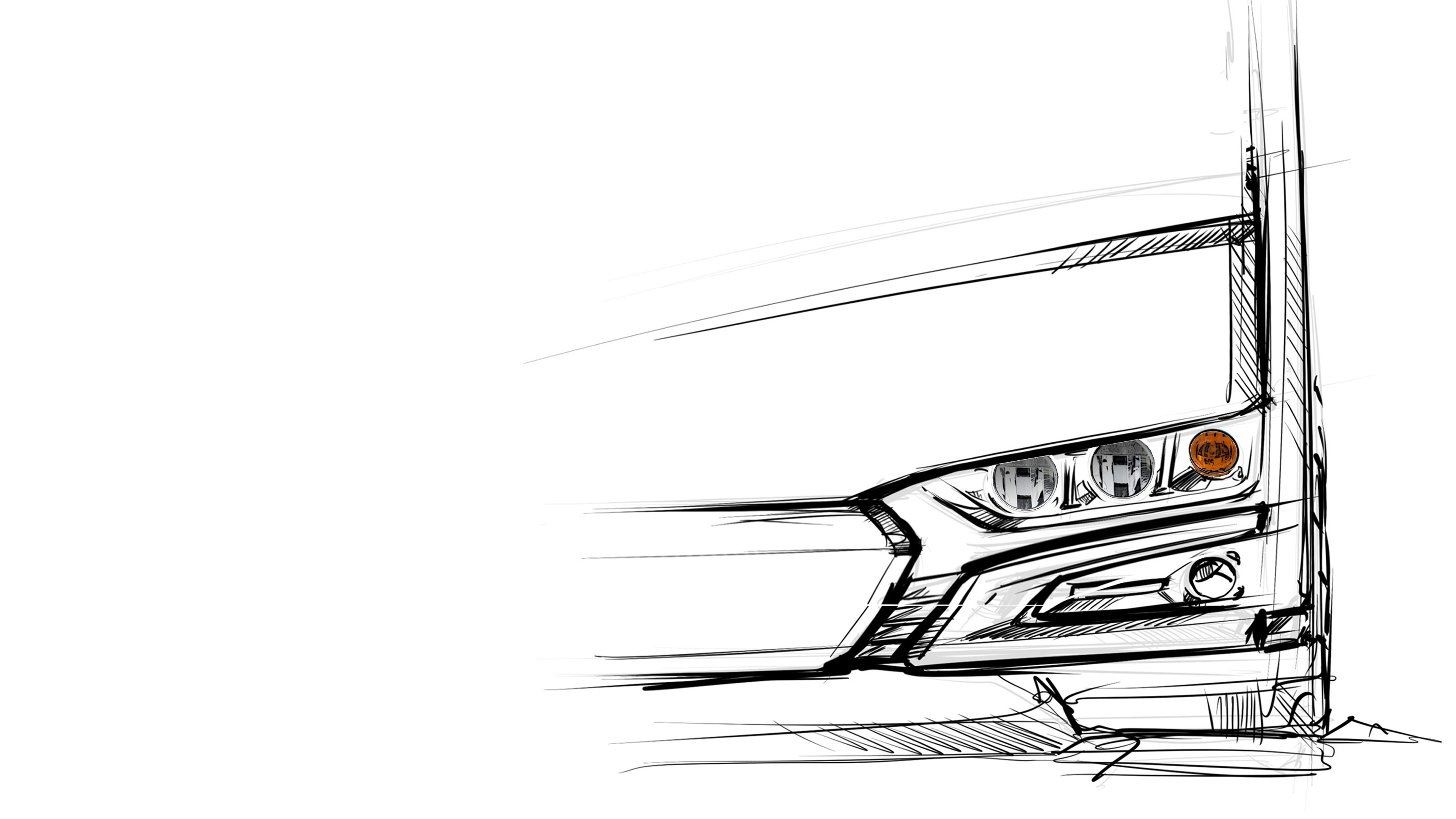

The headlights with RFT technology illuminate a wider area of the roadside and provide friendlier light, resulting in improved driver comfort. Thanks to the use of a smooth glass, the headlight casings can be slimmer and the lamps are smaller. This means more flexibility in the use of the headlights in vehicle design.

When it comes to headlights, it is extremely important to direct the light so that it does not dazzle other road users. RFT technology appears to be the best solution for public transport vehicles, as the precisely directed reflector gives more control over the beam shape and generates more light than lenticular lamps.

By illuminating a wider area to the side, e.g. around a bus, RFT technology headlamps provide better comfort for the driver and offer more friendly light to road users without dazzling them. All with fewer LEDs used and lower power consumption.

For manufacturers of public transport vehicles, RFT technology means a lower cost of purchasing lighting while retaining high light parameters. The diode is directed onto a computer-designed reflector that reflects light wider and closer than a lens. Importantly, the improved parameters of a high-tech product are obtained at the price of older solutions.

With RFT-technology headlamps, it is easy to upgrade the lighting in vehicles where halogen lighting was previously used. No structural changes need to be made thanks to the fact that headlights with RFT technology are equally shallow. RFT headlamps are also cheaper to manufacture and to operate. The diodes use less electricity in both the headlamp and the driving lamp. Electricity consumption is lower, with 12-16W compared to 70W for lens solutions based on halogen technology.

The main beneficiary of RFT technology is public transport and commercial vehicles. Public transport vehicles, need a distributed light reasonably close to the vehicle with maximum illumination to the side. A vehicle with intercity or international range must also have a light with a wider and longer range with very good cut-off and good colour temperature, so as not to dazzle those driving on the opposite side. It is also important that it illuminates the road lane well and does not tire the eyes.

Another group is special and construction vehicles. These vehicles differ from typical “trucks” because they work in harsh and specific conditions, exposed to much more destruction and damage. Working in a quarry, a mine or on a motorway construction site, the vehicles are exposed to stone chipping or working in a humid environment.

Therefore, looking at these conditions, modular headlight solutions based on RFT technology will work perfectly. The level of replacement is not complicated and the cost of their maintenance is low. By having each light function separately, you can be sure that one of them will always work. You can also adjust the colour of the light, as well as other parameters, of the individual modules, which you will not have if you break up an integrated headlight.